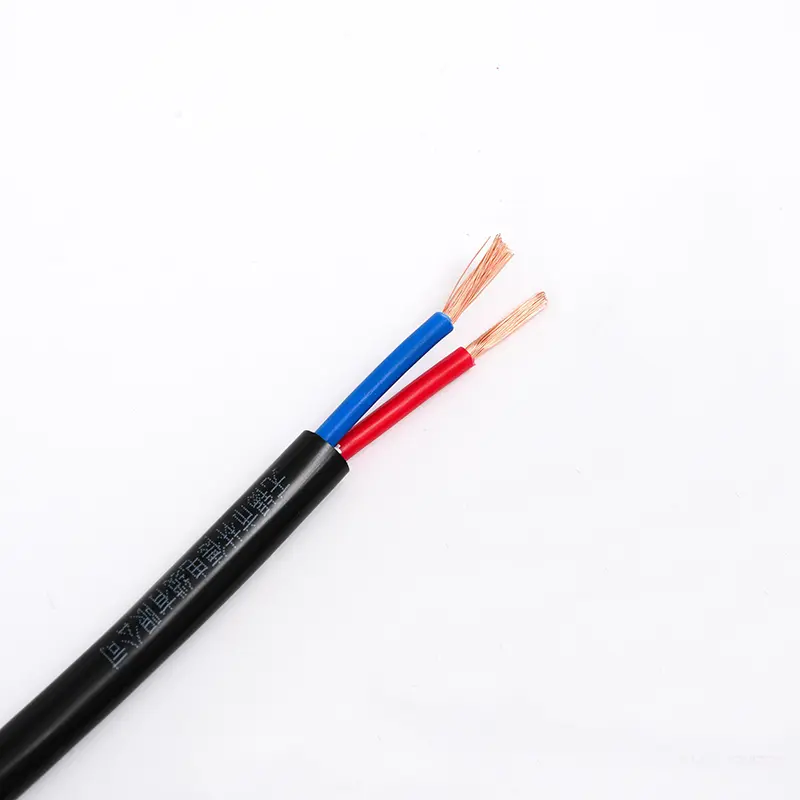

60227 IEC 52 RVV Light polyvinyl chloride sheathed cord

Construction

(1) Conductors

Number of conductors:2 and 3.

The conductors comply with the requirements given in lEC 60228 for class 5

(2) Insulation

The insulation is polyvinyl chloride compound of type PVC/D applied around each conductor.

(3) Assembly of cores

Circular cord:the cores are twisted together.

Flat cord:the cores are laid parallel.

(4) Sheath

The sheath is polyvinyl chloride compound of type PVC/ST5 applied around the cores.

The sheath fill the spaces between the cores, thus forming a filling, but it is not adhere to the cores. The assembly of cores is surrounded by a separator, which is not adhere to the cores.

The assembly of circular cords has a practically circular cross-section.

Technical Performance

Maximum conductor temperature in normal use: 70°C

The use of the cable type 60227 lEC 52 comply with lEC 62440, which provides guidance on the safe use of electric cables with a rated voltage not exceeding 450/750 V.

Parameter Table

| 1 | 2 | 3 | 4 | 5 | 6 |

|

Number and nominal cross- sectional area of conductors mm² |

Thickness of insulation |

Thickness of sheath |

Mean overall dimensions |

Minimum insulation resistance at 70°C MΩ ·km |

|

|

Specified value mm |

Specified value mm |

Lower limit mm |

Upper limit mm |

||

| 2 × 0.5 | 0.5 | 0.6 | 4.6 or 3.0 × 4.9 |

5.9 or 3.7 × 5.9 |

0.012 |

| 2 × 0.75 | 0.5 | 0.6 | 4.9 or 3.2 × 5.2 |

6.3 or 3.8 × 6.3 |

0.010 |

| 3 × 0.5 | 0.5 | 0.6 | 4.9 | 6.3 | 0.012 |

| 3 × 0.75 | 0.5 | 0.6 | 5.2 | 6.7 | 0.010 |

Advantages

(1) Consistent Product Quality

We achieve superior product consistency through:

● Premium-grade material procurement

● State-of-the-art production methodologies

● Multi-layered quality verification process:

- ○ Incoming material analysis

- ○ Production phase monitoring

- ○ Intermediate product validation

- ○ Final output certification

● Comprehensive digital documentation

● Physical sample preservation

● Complete batch traceability

This systematic approach guarantees products that consistently meet and exceed customer expectations.

(2) Industry-Leading Delivery Speed

Our supply chain advantages include:

● Extensive finished goods inventory

● Strategic work-in-progress reserves

● Adaptive manufacturing protocols

● Real-time production scheduling

These capabilities enable us to:

● Accommodate emergency orders

● Handle volume fluctuations

● Meet critical deadlines

● Maintain quality benchmarks

(3) Tailored Customization Services

Our customization framework features:

● Specialized project coordination

● Cross-functional expert teams:

- ○ Research & Development

- ○ Technical Sales

- ○ Production Engineering

- ○ Quality Assurance

- ○ Customer Support

● Integrated workflow management

● Tailored technical specifications

This structure delivers precision-engineered solutions aligned with each client's unique operational requirements.