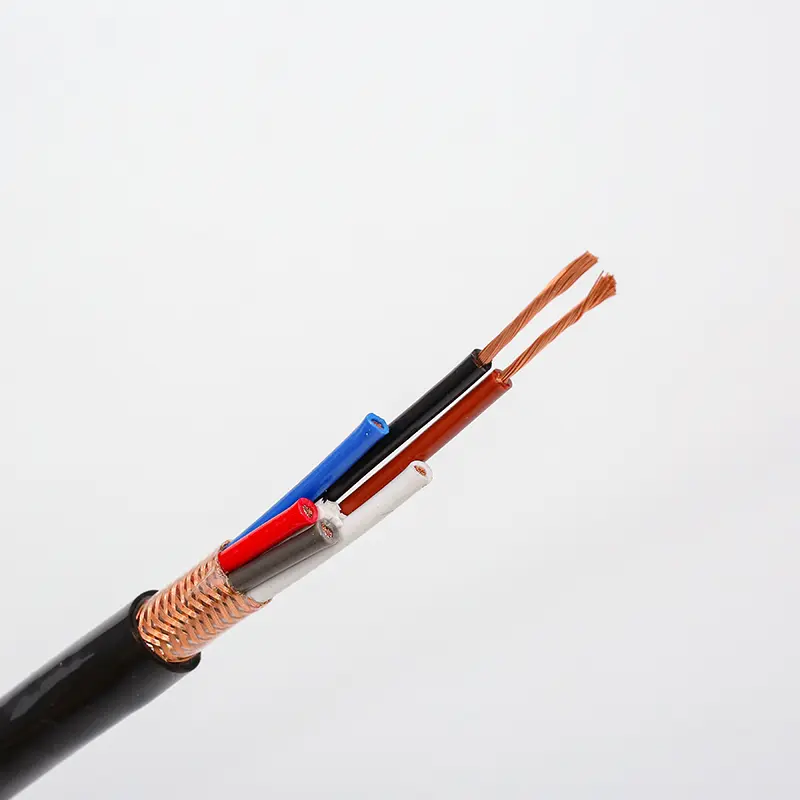

60227 IEC 53 RVV Ordinary polyvinyl chloride sheathed cord

Construction

(1) Conductors

Number of conductors:2,3,4 or 5.

The conductors comply with the requirements given in lEC 60228 for class 5 conductors.

(2) Insulation

The insulation is polyvinyl chloride compound of type PVC/D applied around each conductor.

(3) Assembly of cores and fillers,if any

Circular cord:the cores and the fillers are twisted together.

Flat cord:the cores are laid parallel.

For a circular cord having two cores, the space between the cores is filled either by separate fillers or by the sheath filling the interstices.

Any filler are not adhere to the cores

(4) Sheath

The sheath is polyvinyl chloride compound of type PVC/ST5 applied around the cores.

The sheath fill the spaces between the cores, thus forming a filling, but it is not adhere to the cores. The assembly of cores is surrounded by a separator, which is not adhere to the cores.

The assembly of circular cords has a practically circular cross-section.

Technical Performance

Maximum conductor temperature in normal use: 70°C

The use of the cable type 60227 lEC 53 comply with lEC 62440, which provides guidance on the safe use of electric cables with a rated voltage not exceeding 450/750 V.

Parameter Table

| 1 | 2 | 3 | 4 | 5 | 6 |

|

Number and nominal cross- sectional area of conductors mm² |

Thickness of insulation |

Thickness of sheath |

Mean overall dimensions |

Minimum insulation resistance at 70°C MΩ ·km |

|

|

Specified value mm |

Specified value mm |

Lower limit mm |

Upper limit mm |

||

| 2 × 0.75 | 0.6 | 0.8 | 5.7 or 3.7 × 6.0 |

7.2 or 4.5 × 7.2 |

0.011 |

| 2 × 1 | 0.6 | 0.8 | 5.9 or 3.9 × 6.2 |

7.5 or 4.7 × 7.5 |

0.010 |

| 2 × 1.5 | 0.7 | 0.8 | 6.8 | 8.6 | 0.010 |

| 2 × 2.5 | 0.8 | 1.0 | 8.4 | 10.6 | 0.009 |

| 2 × 4 | 0.8 | 1.1 | 9.7 | 12.1 | 0.007 |

| 3 × 0.75 | 0.6 | 0.8 | 6.0 | 7.6 | 0.011 |

| 3 × 1 | 0.6 | 0.8 | 6.3 | 8.0 | 0.010 |

| 3 × 1.5 | 0.7 | 0.9 | 7.4 | 9.4 | 0.010 |

| 3 × 2.5 | 0.8 | 1.1 | 9.2 | 11.4 | 0.009 |

| 3 × 4 | 0.8 | 1.1 | 10.3 | 12.8 | 0.007 |

| 4 × 0.75 | 0.6 | 0.8 | 6.6 | 8.3 | 0.011 |

| 4 × 1 | 0.6 | 0.9 | 7.1 | 9.0 | 0.010 |

| 4 × 1.5 | 0.7 | 1.0 | 8.4 | 10.5 | 0.010 |

| 4 × 2.5 | 0.8 | 1.1 | 10.1 | 12.5 | 0.009 |

| 4 × 4 | 0.8 | 1.2 | 11.5 | 14.3 | 0.007 |

| 5 × 0.75 | 0.6 | 0.9 | 7.4 | 9.3 | 0.011 |

| 5 × 1 | 0.6 | 0.9 | 7.8 | 9.8 | 0.010 |

| 5 × 1.5 | 0.7 | 1.1 | 9.3 | 11.6 | 0.010 |

| 5 × 2.5 | 0.8 | 1.2 | 11.2 | 13.9 | 0.009 |

| 5 × 4 | 0.8 | 1.3 | 12.8 | 15.9 | 0.007 |

Advantages

(1) Consistent Product Quality

Our company utilizes high-quality raw materials and advanced manufacturing processes to ensure that the products meet customers' specifications and performance requirements. Supported by a comprehensive inspection system, we rigorously monitor quality from four key stages: raw material inspection, in-process inspection, semi-finished product inspection, and finished product inspection. Throughout production, we strictly implement data collection protocols and retain product samples, ensuring full traceability for every item.

(2) Industry-Leading Delivery Speed

We maintain ample inventory across all product categories, enabling us to promptly fulfill urgent customer demands. Additionally, our strategic stock of semi-finished products, combined with a highly flexible production management approach, allows us to efficiently address diverse and time-sensitive customer requirements.

(3) Tailored Customization Services

For customized product requests, we have established a sophisticated and streamlined workflow. Each custom project is supported by a dedicated one-on-one service team, comprising experts from R&D, sales, production, after-sales, and other relevant departments. This structure ensures professional and efficient solutions tailored to the customer's specific needs.