Maximize Current Carrying Capacity of Copper Conductors - Top China Manufacturer

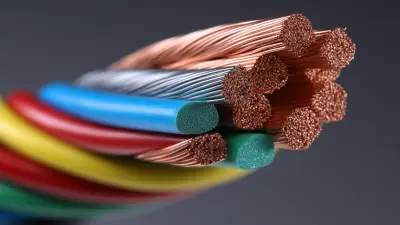

At Wuxi Linde Cable Co., Ltd., we specialize in manufacturing high-quality copper conductors essential for efficient power transmission across various industries. Our products adhere to strict industry standards, ensuring reliability and safety for your projects. As a leading supplier, we provide competitive wholesale pricing, making it cost-effective to obtain premium copper conductors. Using advanced technology and expert craftsmanship, we enhance the performance and durability of our cables. Serving sectors such as construction and energy, we prioritize exceptional customer service and prompt delivery. For inquiries or bulk orders, feel free to contact us.How To Evaluate Current Carrying Capacity Of Copper Conductor Sets the Industry Standard Manufacturers You Can Rely On

Evaluating the current carrying capacity of copper conductor sets is crucial for ensuring optimal performance and safety in various applications, including power transmission and telecommunications. The current carrying capacity, often expressed in amperes, refers to the maximum amount of electric current a conductor can carry without exceeding its temperature rating. This is influenced by several factors, including conductor size, insulation type, ambient temperature, and installation conditions. For manufacturers, understanding these parameters is essential to meet industry standards and deliver reliable products that enhance operational efficiency. When selecting a copper conductor set, it's vital to consider the expected load and application environment. Various industry standards and guidelines, such as those established by the National Electrical Code (NEC) and the Institute of Electrical and Electronics Engineers (IEEE), provide comprehensive methodologies for evaluating current carrying capacity. Moreover, partnering with reputable manufacturers known for their adherence to these standards helps ensure that the products meet regulatory requirements and performance expectations. Reliable manufacturers not only provide high-quality copper conductors but also offer insights into the latest technological advancements, helping purchasers make informed decisions that align with their specific needs and industry demands. In an era where energy efficiency and sustainability are paramount, the choice of copper conductors can significantly impact overall project performance. Collaborating with manufacturers who prioritize quality assurance and robust testing protocols will yield solutions that not only comply with current standards but also anticipate future regulatory changes. As procurement professionals, it is essential to stay informed about industry trends and innovations in conductor technologies to select the best options available and secure a competitive edge in the market.

How To Evaluate Current Carrying Capacity Of Copper Conductor Sets the Industry Standard Manufacturers You Can Rely On

| Manufacturer | Conductor Type | Current Rating (A) | Length (m) | Temperature Rating (°C) |

|---|---|---|---|---|

| Manufacturer A | Bare Copper | 100 | 50 | 75 |

| Manufacturer B | Insulated Copper | 90 | 100 | 90 |

| Manufacturer C | Tinned Copper | 120 | 25 | 80 |

| Manufacturer D | Copper Alloy | 150 | 30 | 70 |

| Manufacturer E | Multistranded Copper | 110 | 80 | 85 |

How To Decide Between Current Carrying Capacity Of Copper Conductor Leads the Global Market Industry Giant

E

Emma Carter

Fantastic quality! The customer service representatives were very knowledgeable.

07 July 2025

J

Jacob Mitchell

Highly impressive product and very responsive customer service!

11 May 2025

C

Carter Díaz

Quality that speaks for itself. Service team was very accommodating!

19 June 2025

E

Evan Jenkins

Impressive quality! The customer service team was extremely helpful.

18 May 2025

J

Jeremiah Lee

Incredible product! They stand behind their quality with excellent service.

04 July 2025

M

Madeline Moore

Outstanding product! The follow-up service was thorough and professional.

21 June 2025